-

SDS - Slag Detection System (SDS V2)

The AMETEK Land Slag Detection System (SDS V2) delivers improved yields, higher-quality steel and reduces costly downstream processing. There are additional benefits in reduced ladle refractory wear.

2025-01-21

-

OPI – OSCILLATION PATH INSTRUMENT MOULD OSCILLATOR CHECKER

Mould oscillation is crucial in continuous casting since it has a direct impact on steel quality. The oscillation profile, stroke and frequency have an important influence on oscillation marks, mould lubrication, heat transfer, mould friction and surface quality. The ability to monitor the oscillation parameters is therefore crucial to improve the steel quality, while reducing breakout risk and maintenance costs.

2025-01-15

-

GAP CHECKER MANUAL MEASUREMENT OF ROLL GAP

his simple and very efficient tool was especially developed for continuous casting plants for quick, easy and precise measuring, control and adjustment of the roller gap.It helps to optimize the casting process and therefore the casting products, which must comply with high quality requirements. The internal quality of slabs is strongly influenced by the alignment of the strand guide rollers within the strand guide.

2025-01-07

-

System for Early Slag Detection in the Process of Steel Pouring from Steel Ladle into Tundish «Vibration Slag Detection System for Ladle (VSDL)»

Vibration Slag Detection System for Ladle (VDSL) is designed for automatic detection of slag penetration into liquid steel jet while pouring form Steel Ladle to Tundish. Upon detection of slag the system generates sound alarm to the operator and/or signal to operate the slide gate of the ladle.

2024-12-25

-

Ladle Slag Detection

The EMLI III Ladle slag detection system utilizes advanced electronics and specially designed sensors to identify slag presence in the ladle’s well-block area.

The sensors’ unique design and strategic placement enable the EMLI system to produce a dependable and precise slag alarm well before a human operator can detect it.

This technology allows users to optimize yield while significantly reducing slag carryover.2024-12-20

-

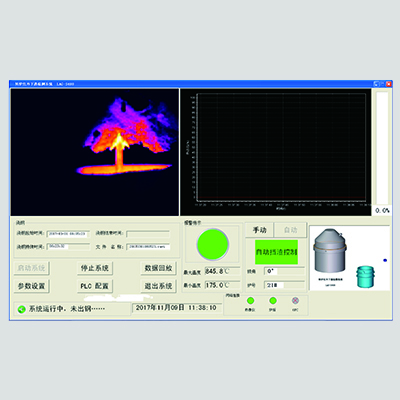

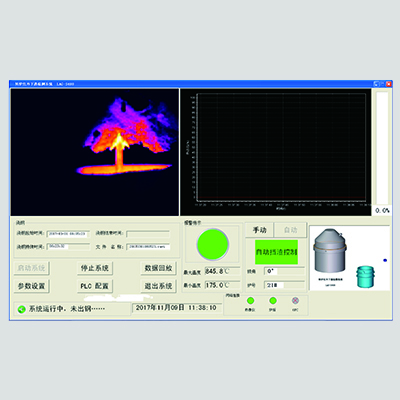

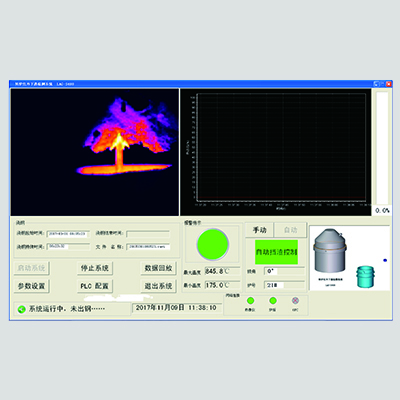

Clean Steel with Thermographic Slag Detection TSD 2.0

The ever-increasing demands on the degree of steel purity require the slag-free transfer of liquid steel from the oxygen steel converter or electric furnace into the ladle. A prerequisite for this demand is that entrainment of slag into the liquid steel can be detected. AMEPA’s latest slag detection system now detects slag flow into the steel on a thermographic basis.

2024-12-11

-

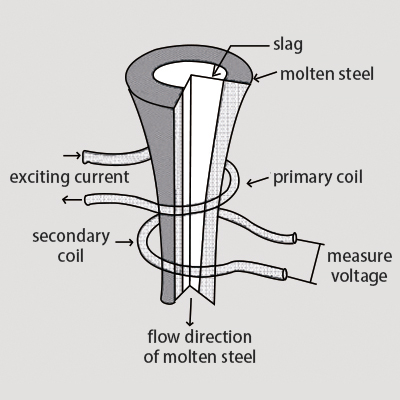

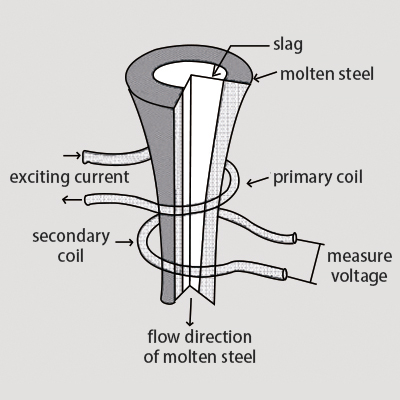

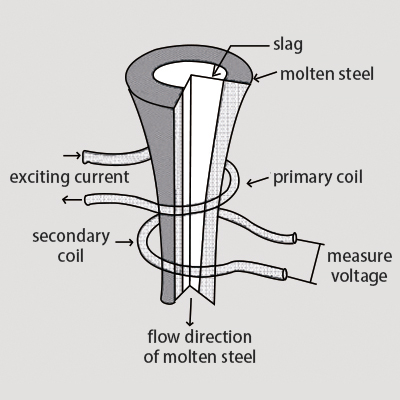

Clean Steel with Electromagnetic Slag Detection ESD 300 and ESD 400

Slag-free transfer of molten steel is critical for prime or scrap and critical for profit or loss in producing high-quality steels. Regardless of whether it is for furnaces, ladles, or distributors: Large quantities of slag must never be transferred to the next vessel.

The ESD Electromagnetic Slag Detection, positioned at the ladle bottom, sounds an alarm as soon as slag flows through and sends a signal to automatically close the slide-gate.2024-12-06

-

MARCEGAGLIA’S PARTNERSHIP WITH PRIMETALS TECHNOLOGIES TO RESULT IN SIGNIFICANT PRODUCTIVITY IMPROVEMENTS

Extensive upgrade of process optimization systems (Level 2) enables production increase from 250,000 to 500,000 tons annually

Primetals Technologies to execute a carefully crafted three-phase plan for immediate, medium-term, and long-term modernization of Marcegaglia’s minimill in Sheffield, the UK

Through-Process Optimization study laid foundation for improvement measures2024-11-28